BLOG POST

Why Side Bias Design Matters

Tonearms, Design

Introduction to tonearm side bias design

The purpose of this article is to explain why a falling weight is the best method of controlling side bias. This method is often dismissed as cheap, fiddly and unsophisticated in reviews. In comparison, you have side bias designs based on springs or magnets with brilliantly engineered precision dials which appear to give immediate control to a fraction of a gram. These impress you with their sophistication and ease of use. They look great and breathe precision engineering. There are however a couple of unanswered tick boxes – are they really accurate and what’s the effect on sound quality? Many discover too late that great looking engineering is not a guarantee of great performance.

There is not much written about the design of side bias devices and even less on how they compare in sound quality and accuracy. Very few realize the extent of the inaccuracy and degradation caused by springs and magnets. However, long ago the inventor of the falling weight method became profoundly dissatisfied with traditional springs and magnets. The reason he came up with the falling weight had nothing to do with reducing costs but was driven by a desire to produce a superior design to all others. We have tested and agree with his findings.

In conclusion, we believe you would prefer years of increased musical pleasure by using a falling weight. This far outweighs saving a few moments of time by using a dial with all the inaccuracies and degradation entailed.

Importance of tonearm side bias

One reason that Origin Live continues to win awards year after year is that we pay enormous attention to details few others consider worthy of investigation. An example of this is tonearm side bias design.

If you care about sound quality, the type of Side Bias design is surprisingly influential. Not just for its function in keeping the cartridge central in the groove but for the effect it has on performance.

The effect of side bias devices

We’ve thoroughly investigated and listened to the effect of various methods used to apply side bias. It’s easy to dismiss this type of research as obsessive and insignificant. However, it’s not difficult to prove the clearly audible artefacts that side bias designs impose on sound quality. If you have a falling weight side bias you can hear the effects for yourself by simply removing or disabling the weight. You will notice an increased openness and freedom in the music (without side bias). The only downside is that separation and imaging suffer slightly but overall the sound is preferable. This effect is much more signnificant when using magnetic or spring devices.

You will read on some forums that people recommend removing side bias altogether for the above reasons – so why use it?

Principles of side bias

When you play music your cartridge experiences an inward side force (which we will explain later). This Side force is detrimental for the following reasons:

- The unequal force on the inner walls of the record groove affects the soundstage image slightly.

- It causes uneven record wear.

- The cartridge suspension is skewed out of alignment from its central sweet spot in the motor mechanism over a period of time. This affects performance to a degree dependent on cartridge suspension – softer suspensions suffer badly.

A good side bias neutralises these effects by counteracting the induced inwards force with an equal and opposite outwards force. In so doing, the stylus tracks the groove centrally to produce a notably more solid and focused soundstage.

Why sidewall force is inwards

It’s commonly expected that as a tonearm tracks through the grooves it experiences an outwards force. Centrifugal force or differential friction acting on the inner and outer sides of the stylus are intuitive reasons for this misconception.

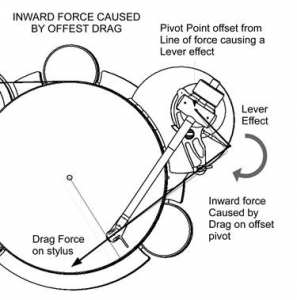

In reality, the frictional force acts tangentially to the groove. This “pull” on the arm is not in line with the arm pivot but offset and thus produces an inwards side force – see diagram below.

Variation in sidewall force

Many years ago extensive research was carried out with regard to sidewall forces. Without going into detail it’s safe to summarise that the inward drag induced force is fairly consistent across the record increasing by about 18% towards the inner tracks (this is not set in stone as it depends on the cut of a record).

For this reason, absolute precision on a side bias device is a little misleading as the requirement varies across a record and varies from record to record. You can safely conclude that side bias settings are about the best compromise.

Requirements of a good side bias device

- Even side force overall tracks: A well designed side bias gives a fairly on the record with a decrease of about 18% for inner tracks – This maintains the centrality of the stylus in the groove and prevents side wall wear.

- Adjustment is repeatable and accurate: Correct setting is determined by trial and error so actual figures on dials are only a guide at best. This is because the internal cable in the arm exerts a significant level of non linear twist in the wrong direction as an arm nears the inner tracks. This is often not considered in side bias designs.

- Low resonance: Avoids audible colouration and performance degradation.

- Effective decoupling: Aids isolation and prevents external vibration feeding into the arm.

- Low friction: Aids side force consistency and prevents tracking problems.

Side bias design variations

Magnetic force – This is a popular choice as it has the advantage of low resonance. The downside is that it has a damping effect which in tests sounds detrimental in giving the music a slightly “sat on quality, lacking speed and life”. Magnets are also non linear and not without problems in providing an even, consistent force across the whole record.

Spiral Spring – This is probably the most popular method and is usually more linear than magnets. However this method introduces damaging resonance and couples the tonearm to a world of hostile vibration. They also exert increasing force towards the inner tracks (the exact opposite of what you want). To overcome this issue a cam and thread may be joined to the end of the spring but this additional complexity has it’s own set of problems.

The detrimental effect of springs in tonearms have been long known to many Rega owners who have followed our advice and disengaged the spring downforce setting in the RB300 (303) arms and above. Others have found remarkable improvement in ripping out the spring entirely but this is not something we recommend as it devalues the arm for resale. Disengaging some of the detrimental effects of the spring is described on the link http://www.originlive.com/rega-tonearm-modifications/rega-tonaearm-tuning-vta-adjustment.html

The effect on sound quality can be best described as a removal of haze and nervousness in the music.

Levers and weights – these devices generally suffer from resonance and poor isolation so they feed vibration into the arm.

Cable or wire twist – Arms with a magnetic bearing are usually held by a vertical thread. Because this twists as the arm traverses across the record it exerts an outward force – adjusting the amount of twist will adjust the side bias. Another variant of this method is used by VPI arms and others where the wiring is used to exert a twist on the arm. The disadvantage of this method is that side bias increases towards the inner tracks and you want the reverse to happen.

Falling weight on a thread – This method overcomes the challenges of side bias better than the aforementioned methods. It has low friction, good isolation, low resonance and even force. The force can also be governed to decrease slightly towards the inner tracks.